37

ADJUSTMENT

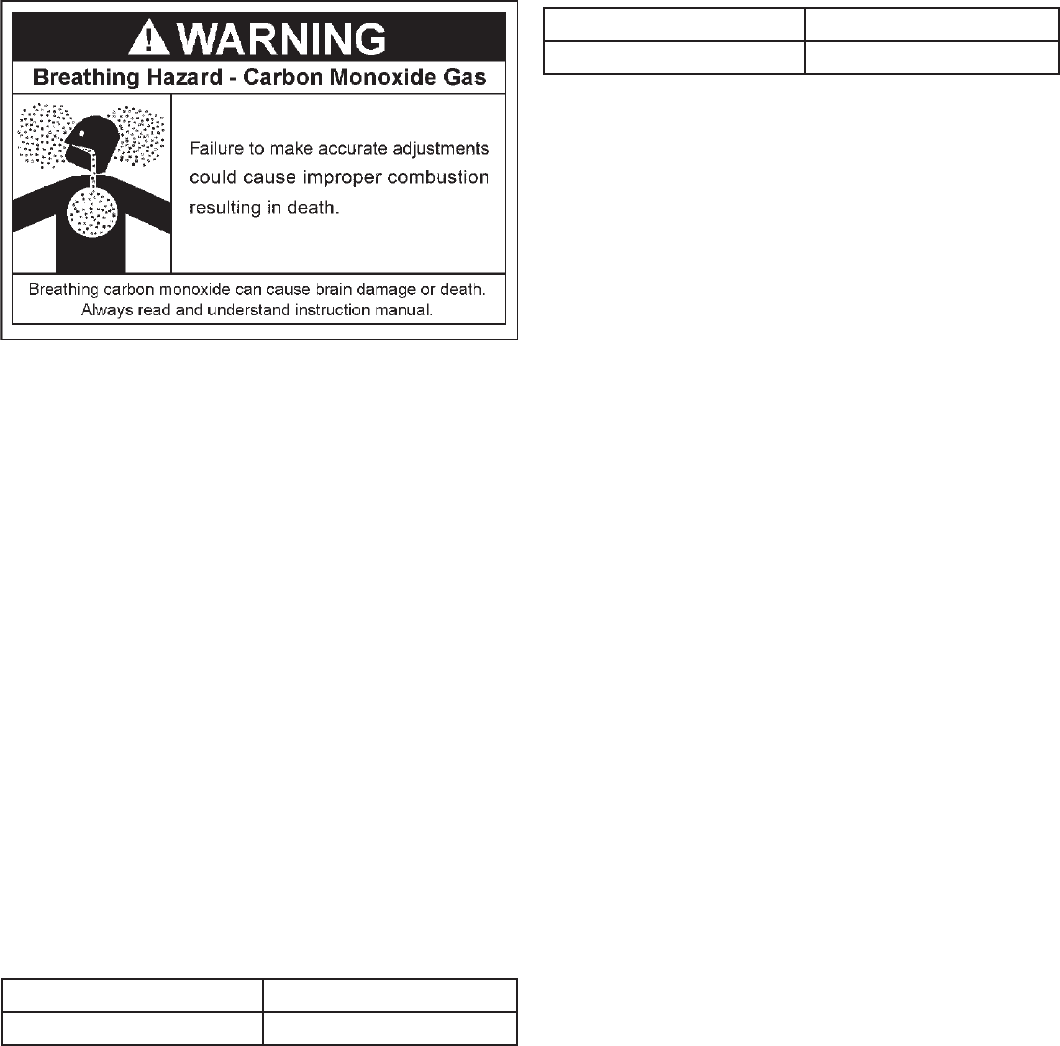

Theremustbesufcientloadtooperatetheboilerathighreto

perform the following adjustments. Start the boiler and observe

proper operating parameters for the system.

Required Tools:

TORX

®

T40 or 5mm hex wrench

3mm or 7/64in hex wrench

Combustion analyzer

The VF 500, 750, and 1000 boilers are equipped with a Honeywell

combined gas/air control and gas safety shut off control valves. The

valve functions in parallel with the variable speed combustion blower to

supplythecorrectgasairratioforoptimumperformanceandefciency.

The combustion blower speed is controlled automatically and determines

the amount of negative pressure experienced by the gas safety shut off/

controlvalves.Thegas/airregulatoradjustsgasowtomaintaintheproper

pressure at the outlet nozzle of the associated valve.

SETTING OF THE TEST MODE

On UIM go to main menu, scroll down to user settings and press select.

Scroll down to MOD mode, press select. Use the up and down keys

toselectoptions:MIN(MINIMUMFIRINGRATE).MAX(MAXIMUM

FIRINGRATE).MOD(FORAUTOMATICMODULATIONMODE).

Press select for the desired option. For checking the combustion setup

on MIN or MAX the boiler will remain in this state for ten minutes before

defaultingtotheMOD(modulation)mode.

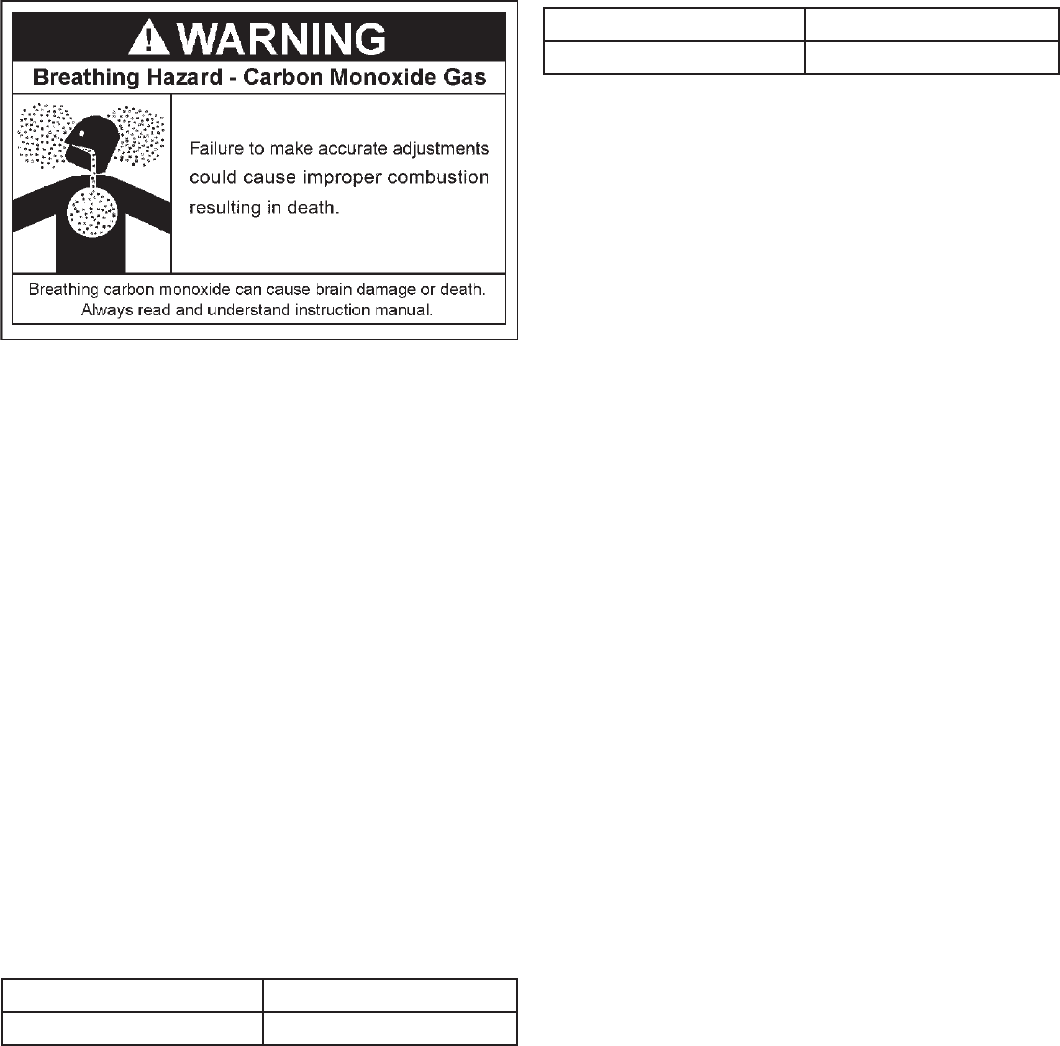

TABLE 11. - HIGH FIRE SETTING

NATURAL GAS 8.5 - 9.0% CO

2

PROPANE 9.5 - 10.5% CO

2

Set boilertothe “Test ModeHigh,”as describedabove, to

achieve maximum firing rate of the boiler. Check combustion

readings using a combustion analyzer. If combustion readings

are not in accordance with the chart above adjust as follows:

remove the flat, round, blue plastic cap from the cover.

Usinga3mm(7/64”)hexwrench,turntheadjustmentscrew

counterclockwise to increase or clockwise to decrease gas flow

and achieve the desired CO

2

level. See Table referenced above

for correct settings. There will be a slight time delay between

the adjustment and the response of the CO

2

measuring

instrument. Adjust the settings in small increments and allow

the combustion readings to stabilize before readjusting. When

desired adjustments are complete, reinstall the blue plastic cap

on the cover. Combustion samples shall be taken within two

feet of the boiler. IMPROPER ADJUSTMENT CAN CAUSE

INCOMPLETE COMBUSTION RESULTING IN DEATH.

TABLE 12. - LOW FIRE SETTING

NATURAL 6.5 - 7.5% CO

2

PROPANE 7.5 - 8.5% CO

2

Set boiler to the “Test Mode Low,” as described above, to

achieve minimum firing rate of the boiler. Check combustion

readings using a combustion analyzer. If combustion readings

are not in accordance with the chart shown above adjust as

follows: remove the cap on the gas regulator using a slotted

screwdriver. This will expose the offset adjustment screw.

Using a TORX

®

T40 or a 5mm hex wrench, carefully adjust

the low fire gas setting to achieve the CO

2

level prescribed

in above reference table. Note: The rotation of the Low

Fire adjustment is opposite of the High Fire as follows:

Clockwise rotation increases gas flow, counterclockwise

rotation decreases gas flow.

Adjustments to the offset pressure regulators should not exceed 1/4

turn at a time before allowing the readings to respond and stabilize.

Afterproperlowreoffsetadjustmentismade,reinstalltheslotted

cap on the regulator.

Following all gas valve adjustments, check for proper light-off and

verify correct fuel/air mix and combustion quality throughout the

entireringrange(fromlowesttohighestfanspeed).

CONTROL SYSTEM

The EMC modulation control system is a fully integrated, state

of the art electronic control system. It consists of sensors, output

devices, a power switch, a 24VAC transformer, wiring, and the

following printed circuit boards:

• ModulationControlBoard(MCB),seeFigure2.

• PowerDistributionBoard(PDB),seeFigure2.

• UserInterfaceModule(UIM),seeFigure20.

TheMCBcontainscircuitryforbothmastercontroland ame

control. Dip switches on the MCB are used to configure the

system.TheUserInterfaceModule(UIM)communicateswiththe

user through a set of touch pads and a 4-line, 20-character LCD

display. The PDB provides connection points for input power, the

water pump, and the transformer. It also distributes power to the

system and contains the system fuses.

The MCB also contains an external communications system

to allow for connection to a PC, a modem, an EMS system,

or something similar. Through this connection, multiple

boilers can also be linked together. CAUTION: The internal

communications cables should never be connected to

the external communications connectors, and vice-

versa.

There are several microcontrollers used on the boards.

These control the temperature and ignition control functions

for the boiler. Inherent in the design are the normal operating

sequences and safety features associated with a gas ignition

control system. The system continuously performs various

diagnostic tests to verify proper appliance and control

operation. Should an unsafe condition occur, the control

will shut down the burner and display a red service light as

well as indicate the cause of the error on the display. The

operating programs for the system are stored in permanent

memory inside the microcontrollers. User-selectable

operating parameters and a history of detected faults are

stored in rewritable memory in the microcontrollers. A loss

of power does not affect either of the memories.